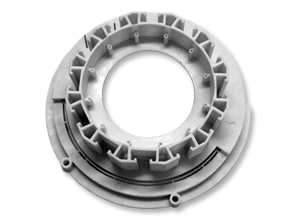

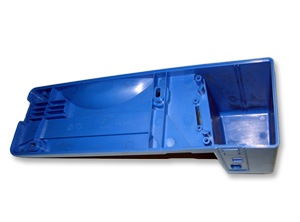

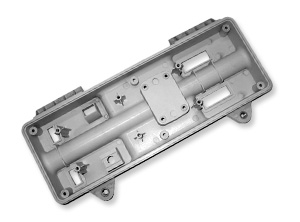

Injection molding

Viewmold has more than 8 injection machines,the tons are from 100T,650T and 2 sets 160 TON doulbe injection molding machines.We provide the best injection molding services for global customers. If you need to custom double injection molds,welcome you to contact us by :sales@viewmold.com or submit a quote online..

Plastic molding is an important method, which is primarily applicable to

thermoplastic plastic molding; Molding can be a complex shape of precision

plastic parts.

The necessity to cool or chill plastics processing machinery is mainly

related to thermoplastic materials. At room temperature thermoplastic materials

(polypropylene, nylon and PET etc) are solid. In order to shape them they must

first be heated to their molten temperature. When molten, they can then be

manipulated (injection molded, extruded etc) to a new shape. When for med to

their new shape they must then be cooled to solidify them. Considerable amounts

of heat energy have to be extracted from the material, the tooling and the

machinery that is doing the forming.

Plastic molding produce components by using techniques such as thermoplastic

or injection molding, blow molding, rotational molding, thermoforming,

structural foam molding, compression molding, and resin transfer molding (RTM).

They also provide services such as mold prototyping, low-volume production,

high-volume production, insert molding, micro-molding, large-part molding,

two-shot injection molding, reel-to-reel molding, machining, hot stamping,

assembly, bonding, packaging and shipping.

There are many different types of plastic molding services. Examples include

blow molding services, compression molding services, dip molding services, film

injection molding services (FIM), and gas assist molding services. Plastic

molding services may also perform reaction injection molding (RIM), resin

transfer molding (RTM), rotational molding, structural foam molding,

thermoplastic injection molding, thermoset casting, thermoset injection molding,

and thermoforming. Vacuum assist resin transfer molding (VARTM), vacuum bag

molding, and vacuum forming services are also available. In terms of material

capabilities, plastic molding services address considerations such as impact

strength, high and low temperature characteristics, warpage, and resistance to

ultraviolet (UV) light. Commodity grade resins are more widely used than other

graded resins and include polyethylene, polypropylene, polystyrene and polyvinyl

chloride (PVC). Engineering grade resins are more difficult to process than

other graded resins, but have characteristics that make them desirable for

specialized use. Widely used engineering grade thermoplastics include acetal,

acrylonitrile butadiene styrene (ABS), nylon, noryl and polycarbonate.

Our company also provides Injection mold tooling design services as DME or HASCO standard